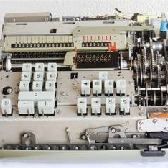

Calculators I added to my collection seldom worked when I got them. This calculators wasn’t any different in that respect. It came in blocked. I never use the motor until I’ve build some confidence that a calculator will work as expected.

So, I used a screwdriver to move the motor on the speed regulator side. While I didn’t use much force I noted that several parts of the machine were bending. Maybe it’s deliberately build that way, but it doesn’t feel well. While working to get it operational I also experienced that it is easily brought into modes from which it is very hard to return to neutral. I learned to be very careful touching controls while handling the machine.

Apart from the more or less usual problems mostly caused by dried oil and fat the following repair actions were performed in 2017:

- On the Reg-III shaft there is a coupling which is intended to create some flexibility between this shaft and the motor + gearbox.

I guess that the manufacturer used a rubber part to create the flexibility, that it has deteriorated and was ever replaced by a piece of hard plastic. I restored the flexibility that I assumed and got rid of all blocks during motor operation.

(Click the Flexble Joint picture below for a pdf with a more detailed description) - Digit input, in particular of digits 1, 2 and 3 often led to an input block. Using a high speed video I noticed that there was quite some bouncing in the toothed arm which enters the digits in Reg-III. A bounce damper cured this problem.

(Click the picture below for a pdf with a more detailed description) - In the electric module on the back of the machine two components were not connected to the relays. I got the impression that they were never properly soldered and came loose (maybe after years) due to vibrations. I had to partly disassemble the module to solder these parts back in place.

- During maintenance in 2022 the shift-right didn’t work reliably anymore. As a consequence the division process often got stuck somewhere in the middle. The cause was probably wear in the transmission of movement from the origin to the connection on Reg-I. (Click the picture below for a pdf with a more detailed description)

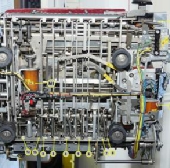

The use of solenoids may give the impression of making the machine much more complex than purely mechanical machines. In order to understand the machine including the role of the solenoids I reverse engineered the electric parts (*). I discovered that the solenoids are only used for rather “safe” actions: Disable of input during operations, digit input and register resets.

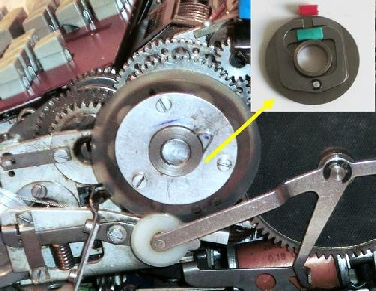

While most machines use a centrifugal switch to limit motor speed, this Brunsviga uses a centrifugal brake. It is a construction similar to that of a drum brake. (See photo below)

Mostly gears are either enabled using a clutch mechanism or shifted in place to drive another gear. In this machine the gears related to register clearing are connected by tilting. They also are only partly toothed. (See photo below as well as the video of this Brunsviga 16E)

(*) Electric diagrams can be downloaded from the assets page on this site.

Click to view a full size picture (opens in a new tab)

Flexible joint

(Click picture to download a description)

Control bars & solenoids

(Click picture to download a description)

Motor speed control

Using a centrifugal brake

Register clear

With tilting gears

Shift-Right repair

(Click picture to download a description)

Bounce damper

(Click picture to download a description

Click the camera icon for a slow motion video)

| Mechanical Calculators |

| Electronic Calculators |

| Typewriters |